Chapter Three – Exciting Times Ahead

Just a week short of our 97th birthday Royde & Tucker Limited is excited to announce the start of a new chapter for the business as we approach our 1st century!

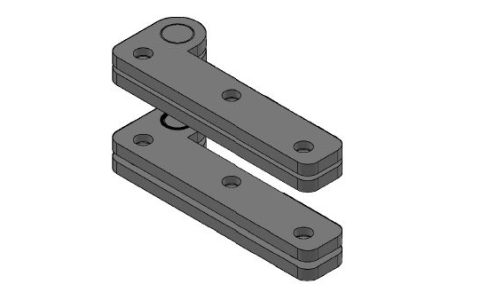

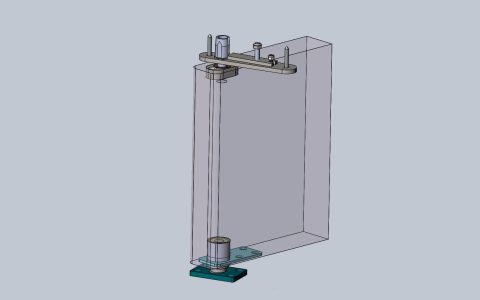

We remain one of the UKs leading independent designer and manufacturer of high performance architectural hardware and the future is bright as we enter a partnership with new investors to take us into the next chapter of this adventure.

After penning chapter one, George Murgitroyd and Richard Tucker handed the baton over to Steve Jenkins and Nick Gadsby, in the early 1970s, to deliver chapter two.

Now, after 48 years with the business, Steve and Nick are taking the opportunity to deservedly sit back and relax as they move on from R&T business. Jon Simms and Simon Gardiner remain at the helm, as Managing Director and Marketing & Sales Director respectively. Jon and Simon have combined experience of 36 years with R&T now to guide us into this next phase – it sounds a lot until you compare it with Steve and Nick’s 96 years!

Jon and Simon were supported in the acquisition from Steve and Nick by Perscitus and Peter Toland. Adrian Field and Charles Shortland from Perscitus will join the Board together with Peter Toland who joins as Non-Executive Chairman. Perscitus and Peter look forward to assisting the Royde & Tucker team in pursuing its growth strategy, both in the UK and internationally.

Adrian Field, Partner at Perscitus said, “This family-owned business has consistently delivered reliable, high quality products to the construction industry for nearly 100 years and we are keen to maintain these standards into the future as we pursue new growth opportunities.”